CYM Materiales SA ofrece a sus clientes una variada gama de equipos de granallado de cinta rotativa que se ajusta a sus necesidades y que, gracias a su exclusivo diseño, aseguran una alta productividad al más bajo costo operativo.

CYM Materiales SA ofrece a sus clientes una variada gama de equipos de granallado de cinta rotativa que se ajusta a sus necesidades y que, gracias a su exclusivo diseño, aseguran una alta productividad al más bajo costo operativo.

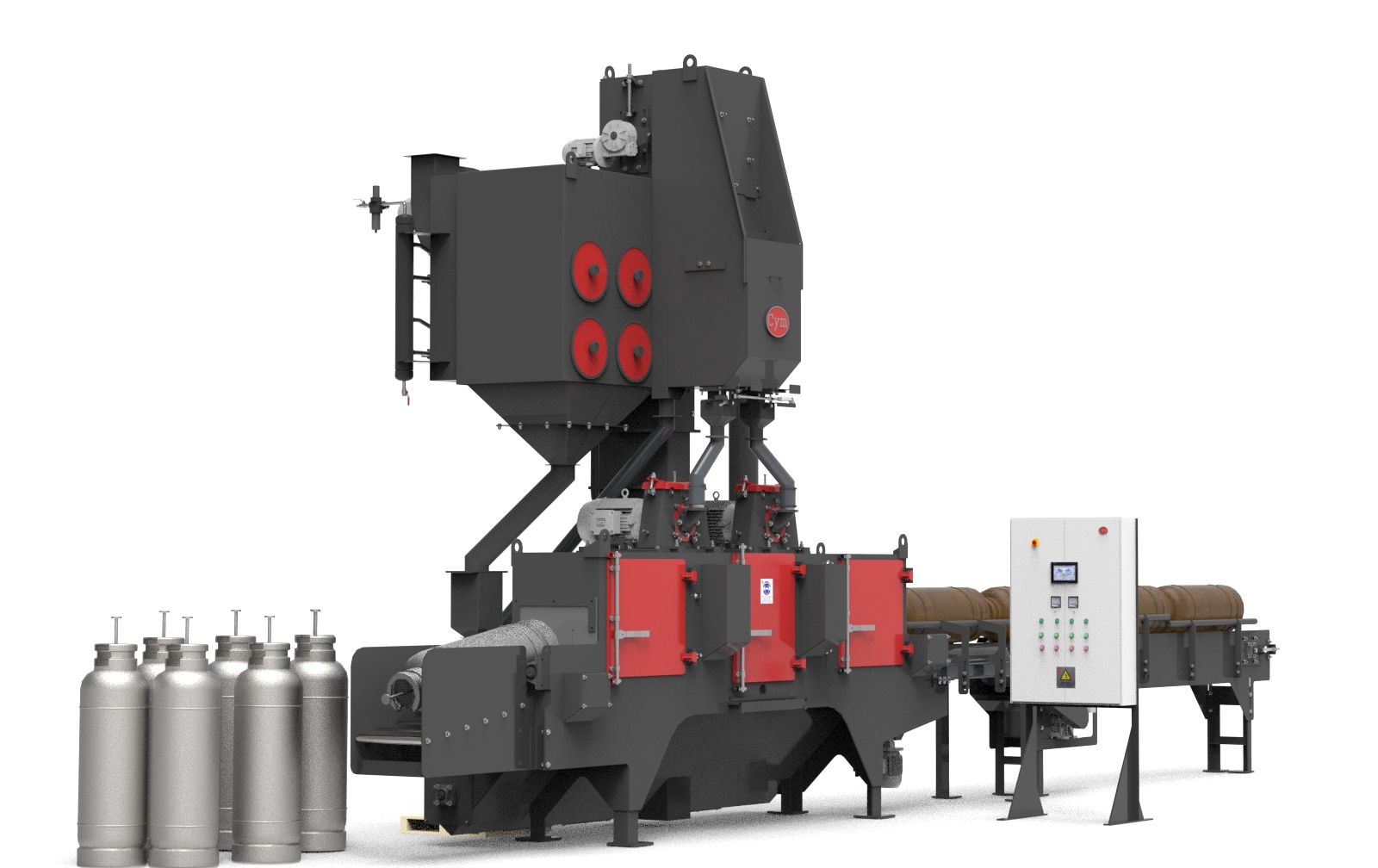

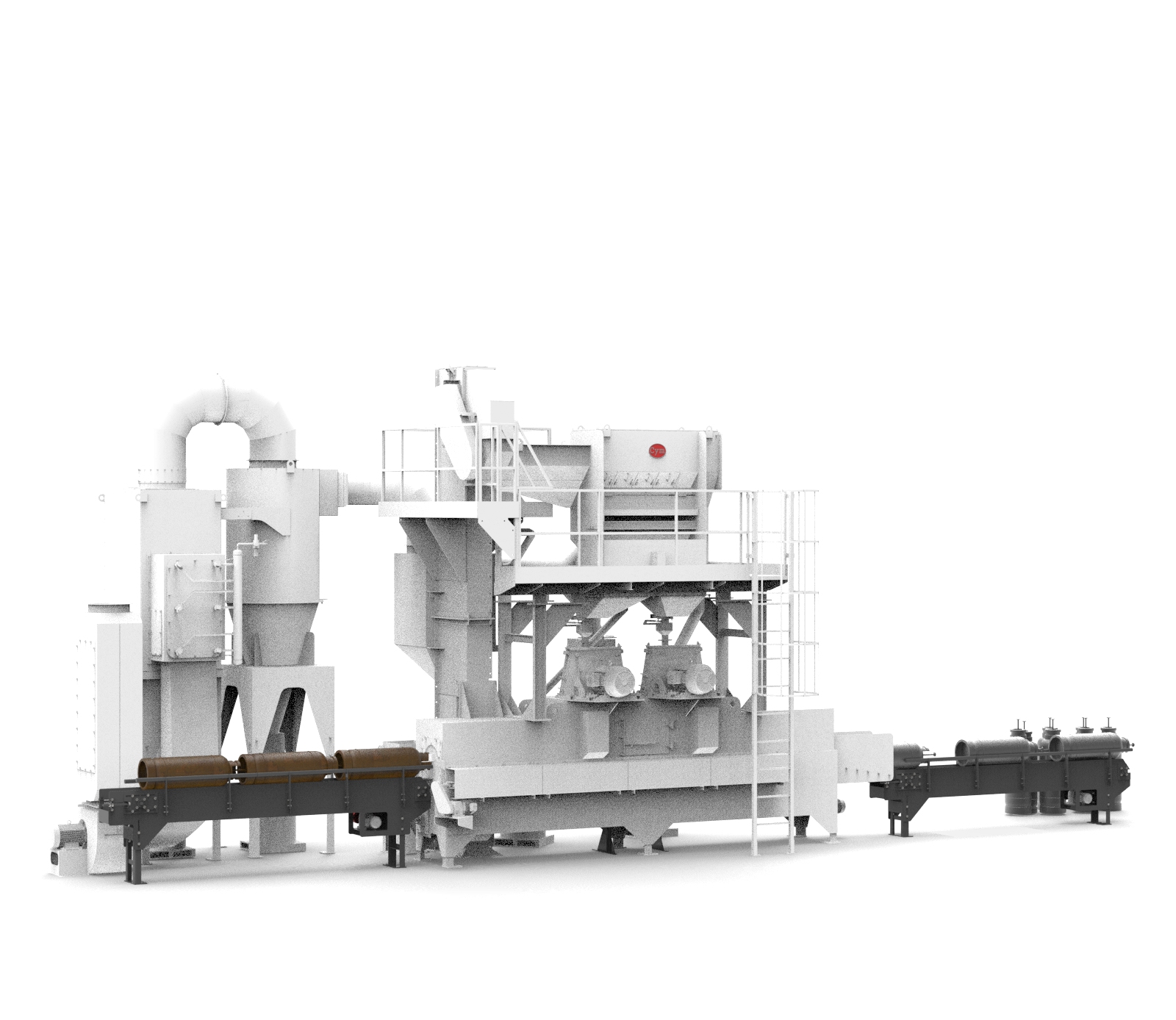

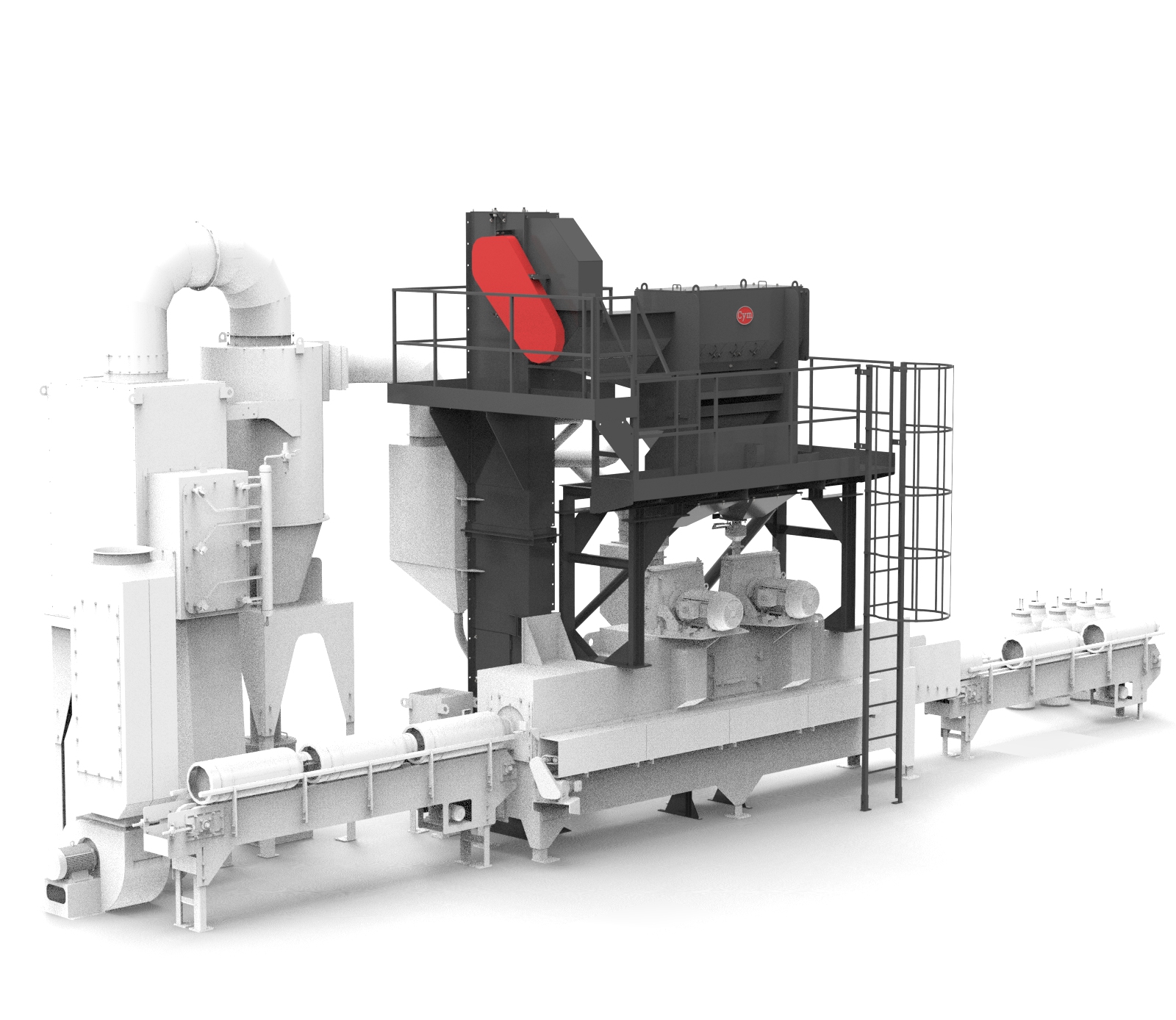

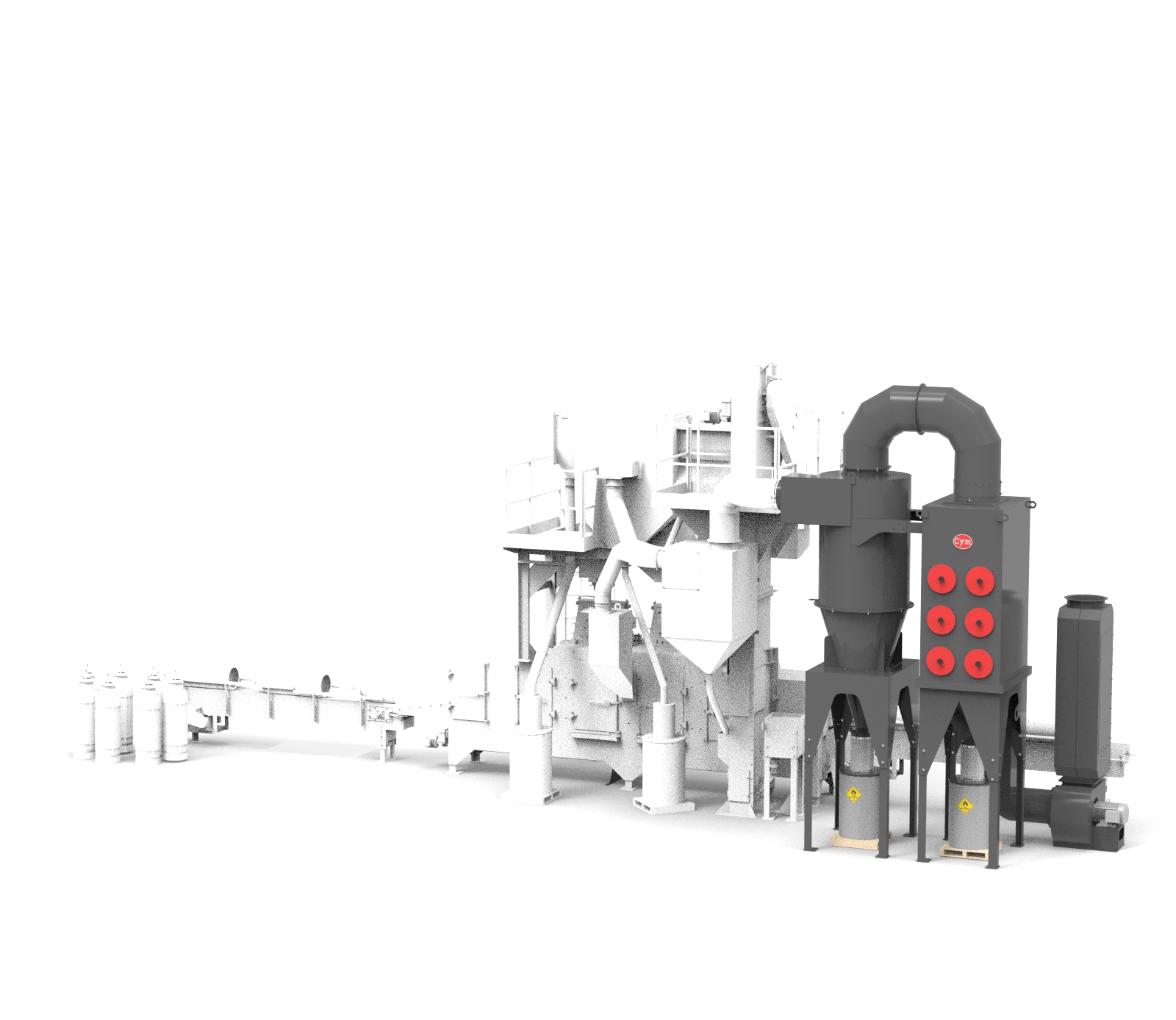

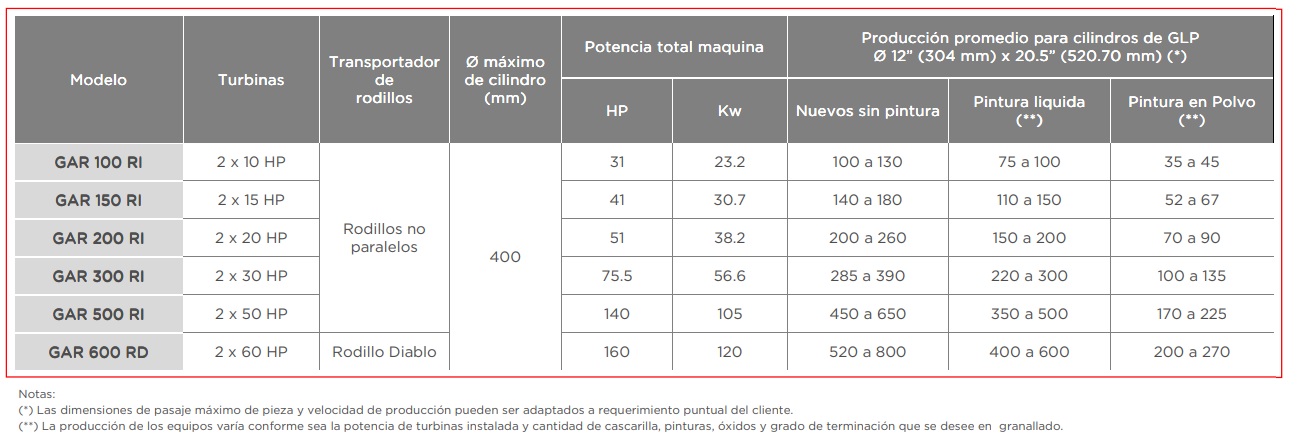

CYM presenta GAR su línea completa de equipos de granallado continuo para cilindros de Gases del Aire, GLP y GNC nuevos o usados, removiendo pinturas líquidas o en polvo, laminillas, óxidos y otros contaminantes, dejando las superficies listas para aplicar todo tipo de revestimiento a un muy bajo costo operativo.

Los equipos GAR atienden las más altas exigencias de trabajo siendo los mismos robustos, confiables y compactos y gracias a un exclusivo diseño y know-how aplicado, aseguran una alta productividad con un bajo costo operativo y de inversión trabajando con un proceso no contaminante del medio ambiente.

Dependiendo del proceso productivo de cada cliente, nuestros equipos se pueden complementar con una serie de adicionales que favorecen la automatización y optimización del mismo anexando transportadores externos de pasaje horizontal o vertical con sistemas de carga y descarga automática y dosificación de ingreso de cilindros en el equipo.

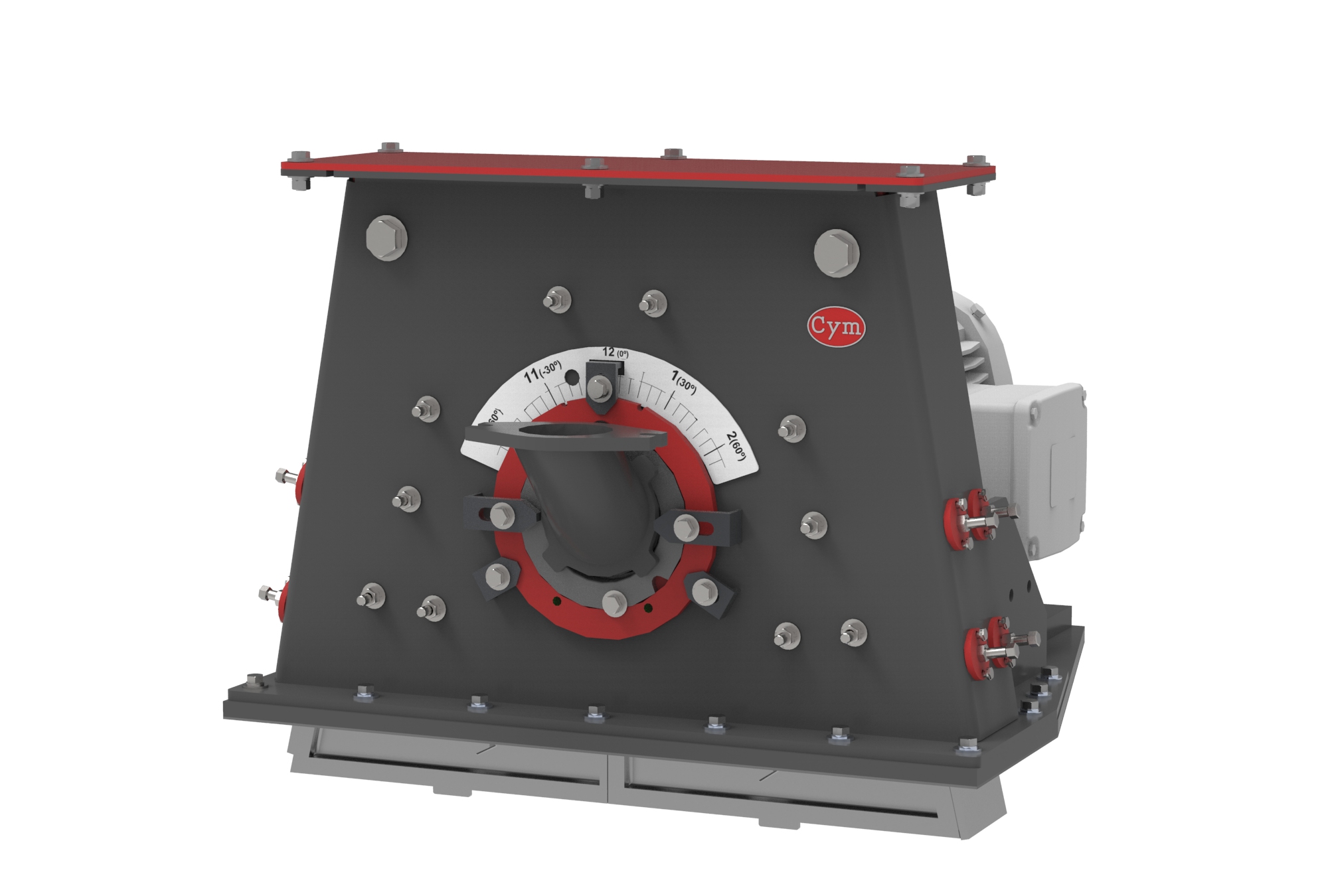

Permite granallar cilindros y camiones tanques que por su tamaño o complejidad no puedan ser procesadas en equipos de granallado automático por turbinas.

Permite granallar cilindros y camiones tanques que por su tamaño o complejidad no puedan ser procesadas en equipos de granallado automático por turbinas.

BRIG. ESTANISLAO LOPEZ N° 6

[S2108AIB] SOLDINI

SANTA FE - ARGENTINA

+54 341 490 1100

info@cym.com.ar

EIZAGUIRRE 1073

[B1754FLA] SAN JUSTO

BUENOS AIRES - ARGENTINA

+54 11 3979-4111 / +54 9 11 3345-8578

cymba@cym.com.ar

SAN MARTÍN 476

[X2645] CORRAL DE BUSTOS

CÓRDOBA - ARGENTINA

+54 9 341 555-5001

corral@cym.com.ar