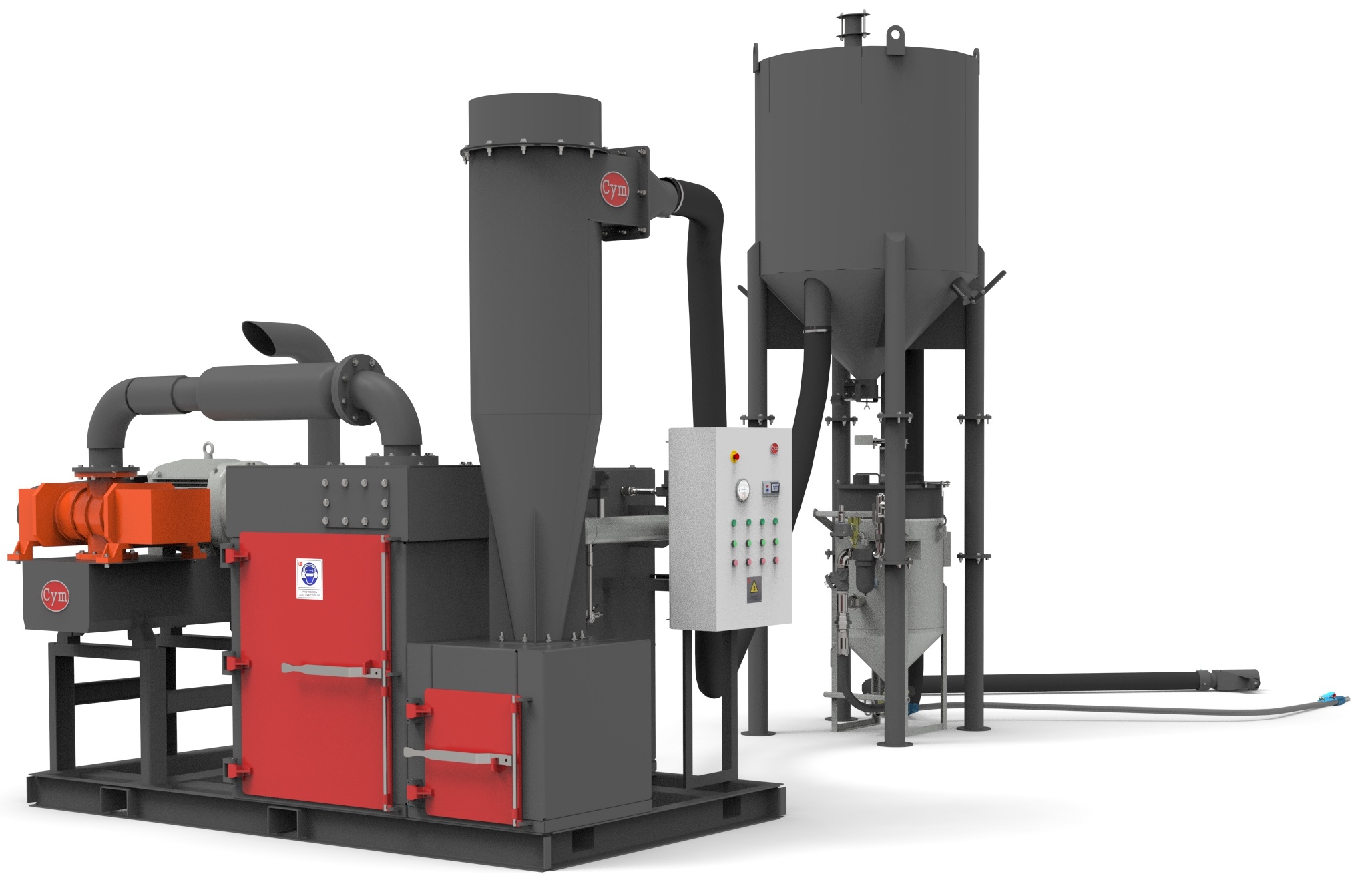

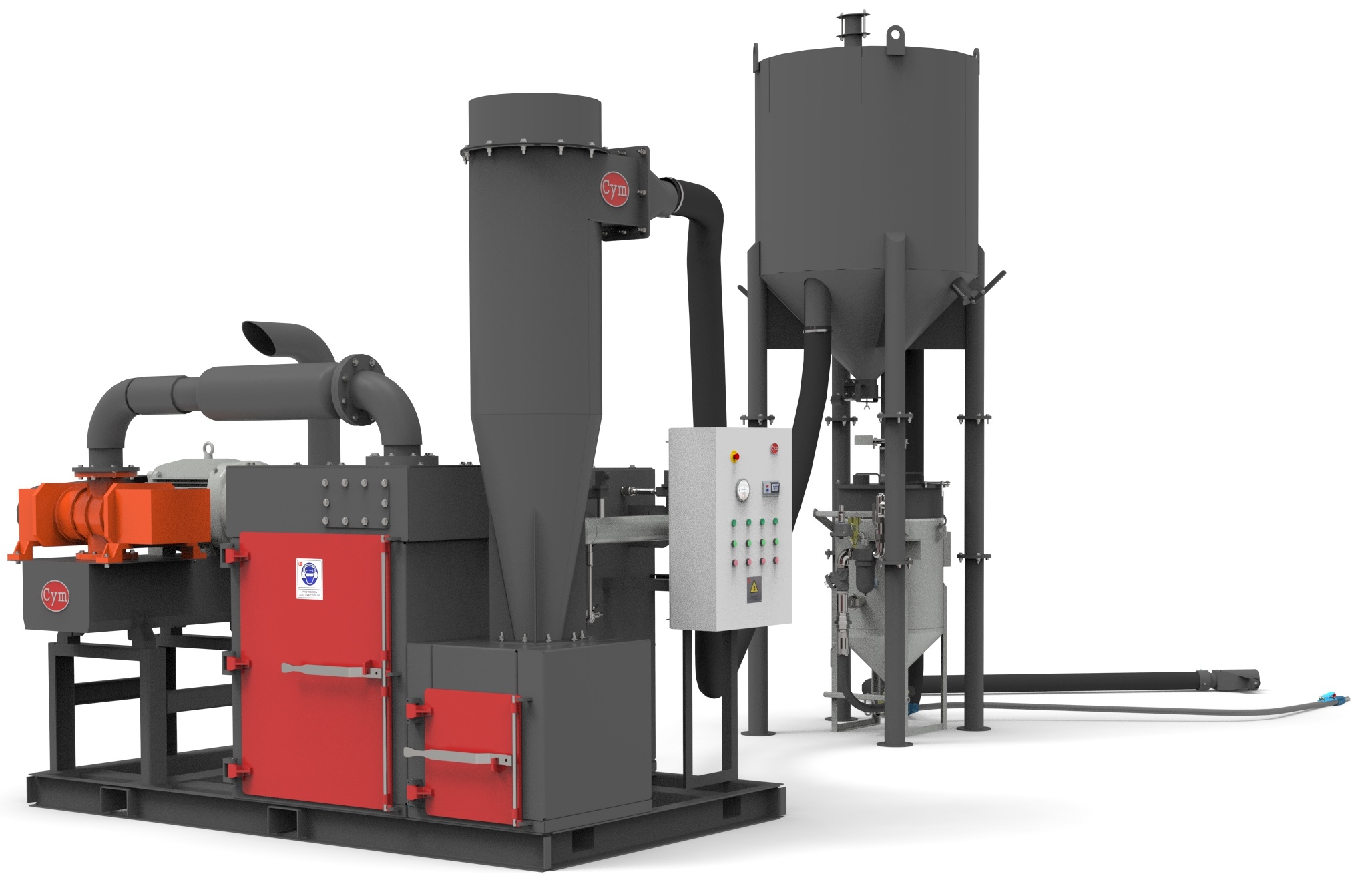

Cym Materiales SA presenta TUB: su línea completa de máquinas para el granallado externo de tubos utilizados en la fabricación de gasoductos, oleoductos, acueductos y otras industrias.

Cym Materiales SA presenta TUB: su línea completa de máquinas para el granallado externo de tubos utilizados en la fabricación de gasoductos, oleoductos, acueductos y otras industrias.

Nuestro amplio portfolio permite granallar tubos de muy variados tamaños y espesores, con diámetros que van de los 12 mm hasta más de 1524 mm, adaptándose a las necesidades específicas de cada cliente.

Gracias a su innovador diseño, el 100% del abrasivo impacta sobre la superficie logrando un óptimo desempeño, alcanzando velocidades de granallado por encima de los 20 m2/minuto con turbinas de alta potencia.

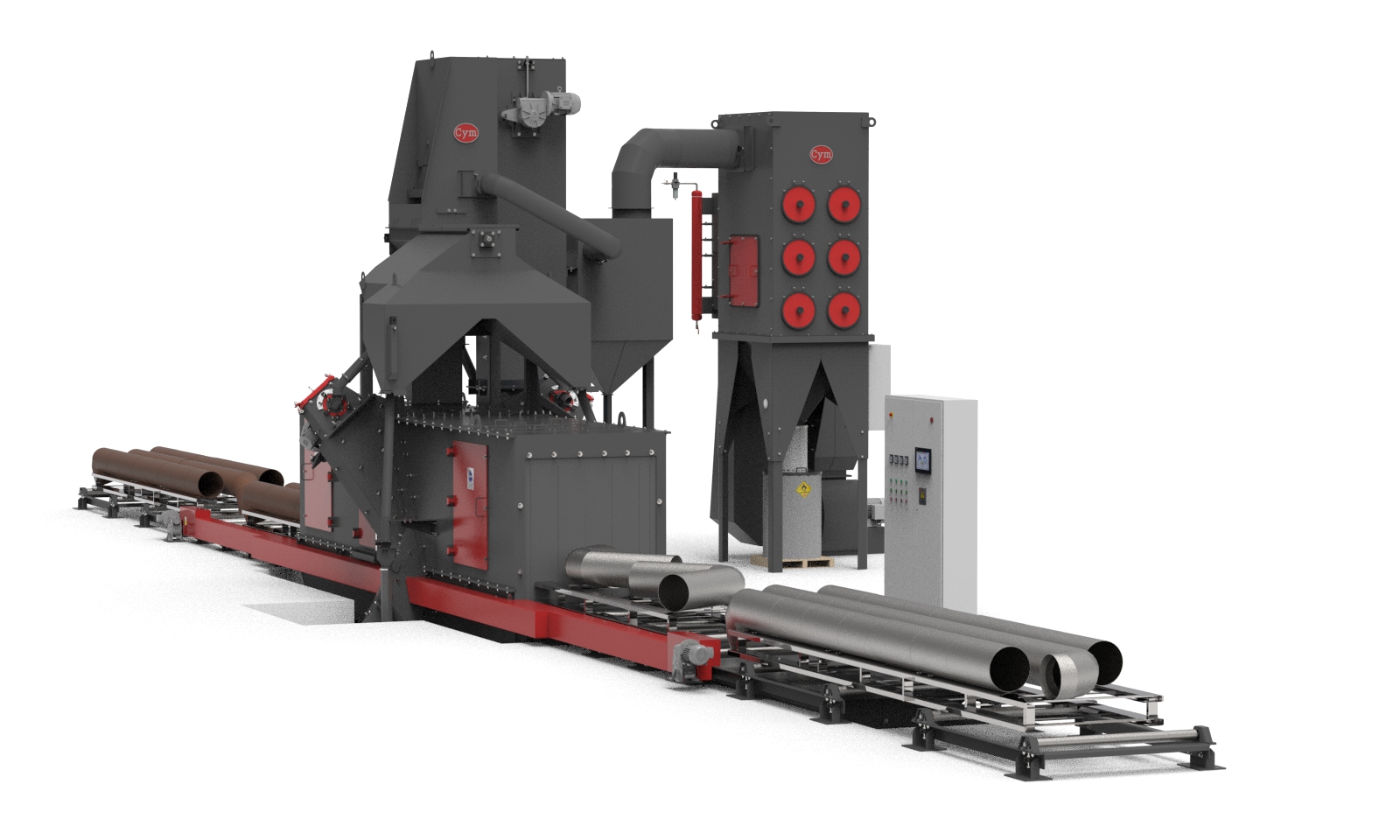

Para garantizar un proceso eficiente y seguro, los equipos se complementan con sistemas de carga y descarga, bancales de acumulación de tubos y transportadores externos de traslación y rotación simultánea.

Características Constructivas

Gabinete Principal

- Estructura fabricada con triple capa de acero

- Estructura externa acero SAE1010

- Doble revestimiento interno

- Acero MN (11-14) cubriendo el 100% del gabinete principal

- Refuerzo adicional en zonas de golpe directo con placas de acero fundido de alto cromo (≥64Rc)

- Sinfín inferior con espiras de acero templado

- Amplias puertas de acceso interior

- Bafles de contención de granalla con múltiples cortinas de goma

- Opcional: deflectores concentradores de granalla

- Mejoran el rendimiento del equipo en tubos de diámetros menores a 4”

- Tres opciones de regulación, fija, manual o neumática

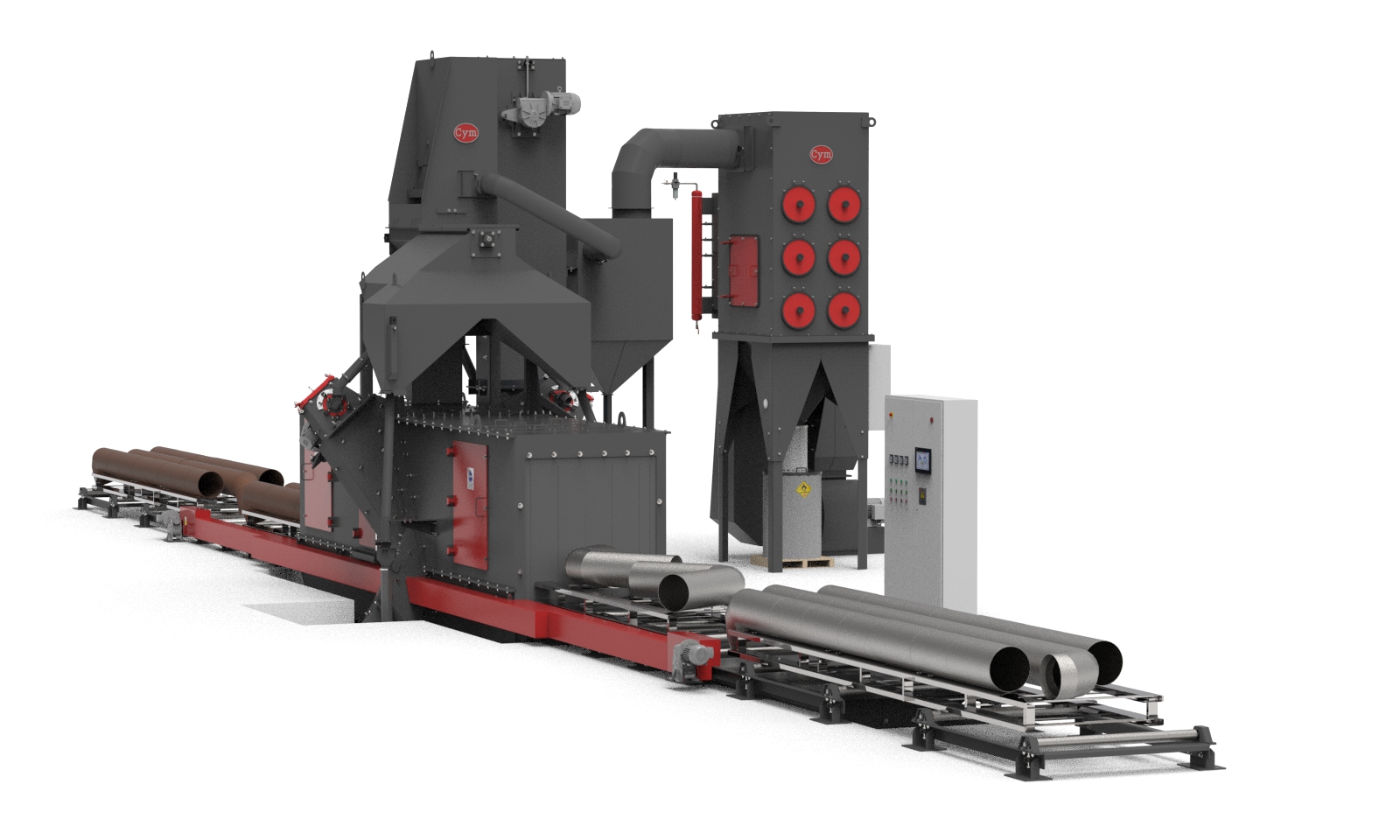

Transportadores de Tubos

- Bancal de entrada y salida acumulación de tubos

- Sistema de carga y descarga de tubos con accionamientos hidráulicos o neumáticos

- Transportadores con sistema de avance y rotación simultanea fabricado con ruedas paralelas

- Largos de transportadores conforme requerimiento

- Velocidad variable de avance de tubos para los distintos diámetros y calidades de granallado

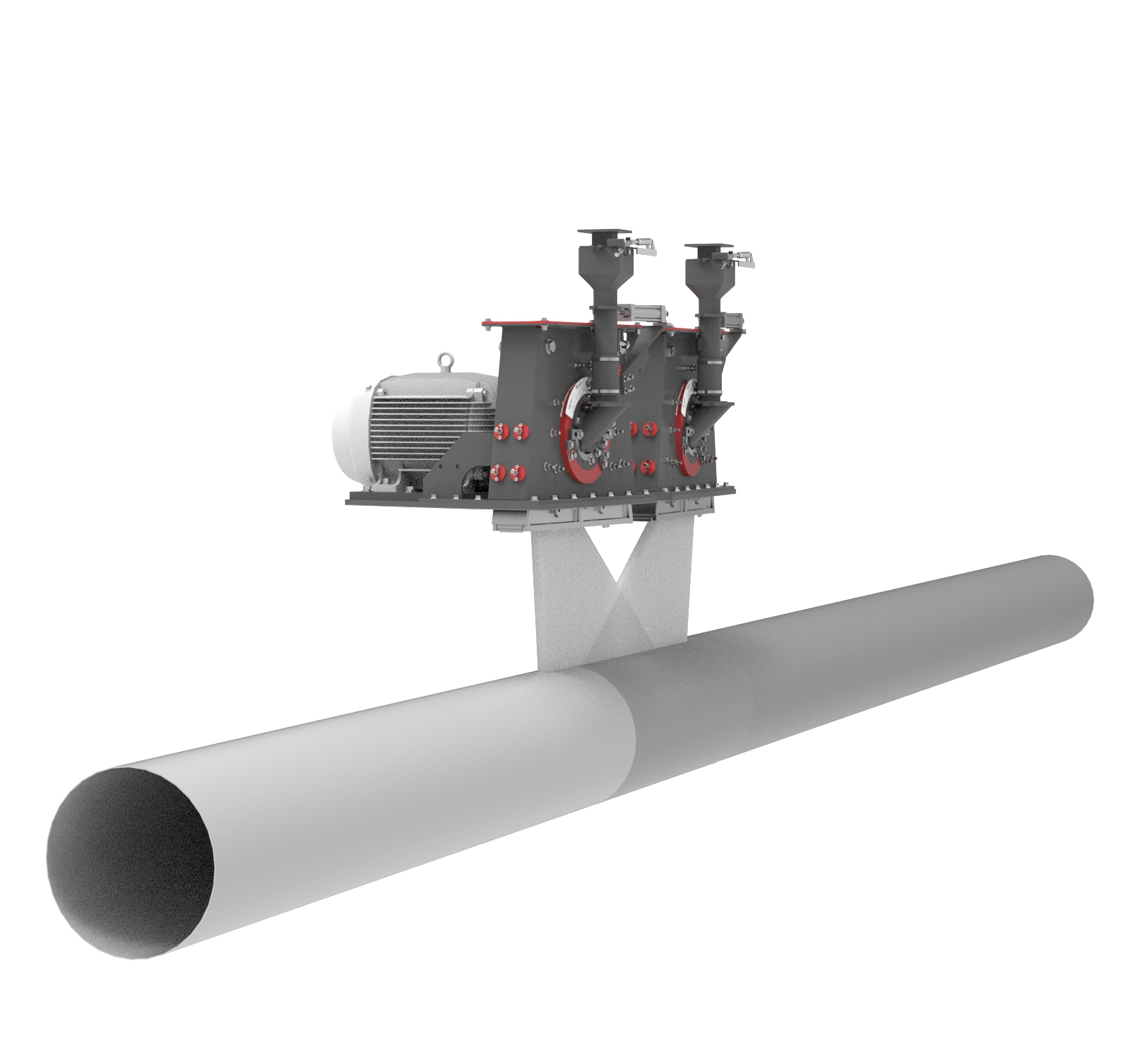

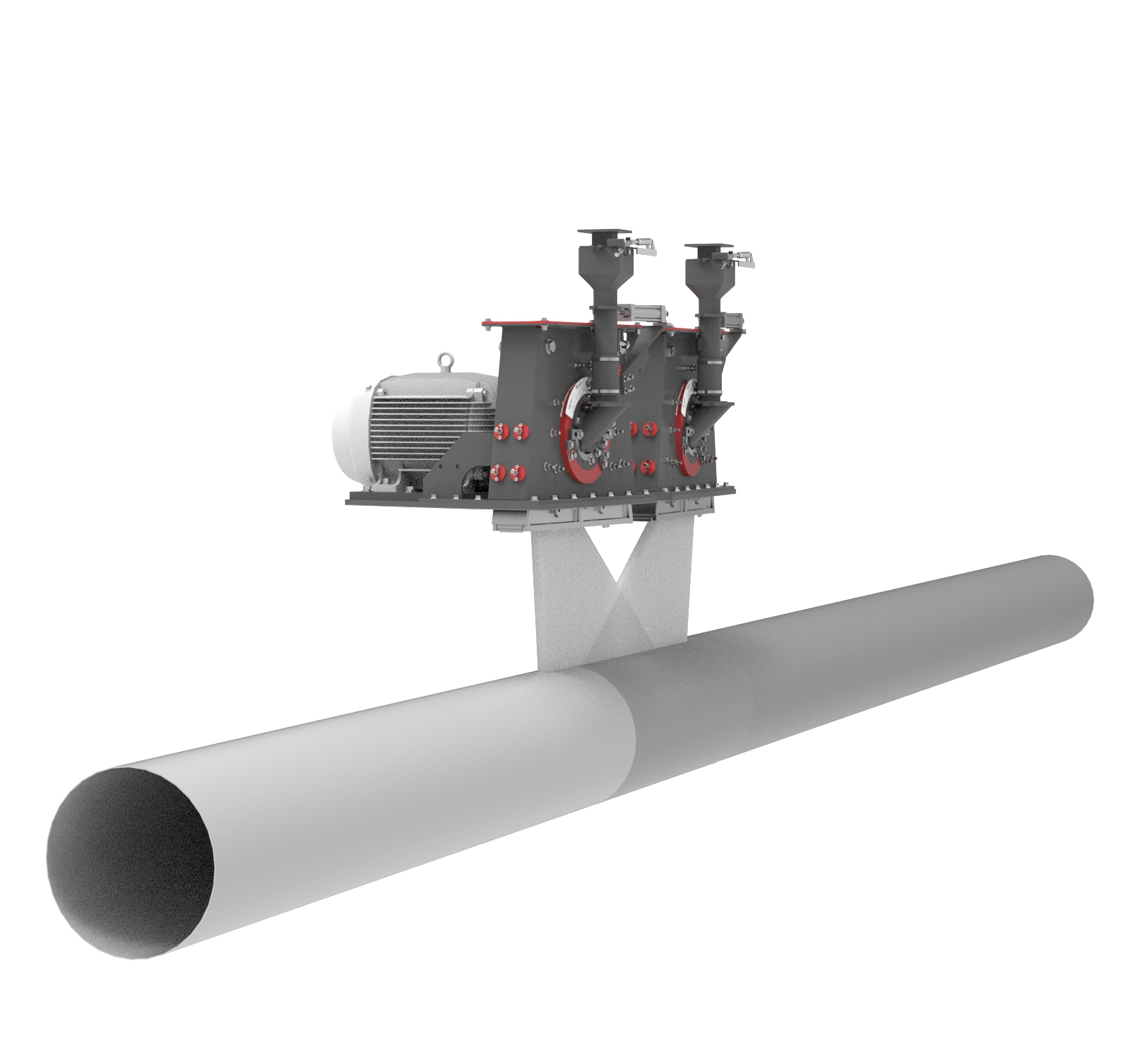

Turbinas de Granallado

- Ubicadas estratégicamente con una correcta distribución de la granalla sobre las piezas a tratar lo que se traduce en una mejor cobertura y en un mejor rendimiento de todo el equipo.

- Turbinas superiores para equipos que procesan tubos hasta Ø 24” y turbinas inferiores para equipos de mayor diámetro

- Potencias desde 10 HP a 100 HP

- Carcasa de turbina fabricadas en acero MN (11-14%) forma junto con el revestimiento interno una doble pared resistente al desgaste.

- Recubrimiento interno de carcasa fabricado en acero alto cromo fundido (≥64Rc)

- Sistema de posicionamiento y fijación de caja de control especial evitando el riesgo de efectuar una incorrecta regulación del punto caliente.

- Cierre laberintico de granalla hermético entre manchón de acople de motor y la carcasa

Sistema de Recirculación y limpieza de Abrasivo

- Elevador de cangilones fundidos SAE1035

- Purificador de abrasivo de alta eficiencia y simple regulación para separación de partículas finas mantiene constante la mezcla operativa de trabajo.

- Sinfín distribuidor de granalla con espiras de acero templado

- Silo de acumulación de abrasivo

- Válvulas de control de flujo de abrasivo

- Plataforma de mantenimiento

- Cargador automático de granalla

Aspirador de Polvo

- Estructura de fabricación –3.2 mm espesor

- Emisiones de partículas menor a 1 mg/m3

- Eficiencia: 0.5 micrones en un 99.9%

- Fácil recambio de elementos filtrantes

- Sistema continuo de limpieza de elementos filtrantes – Pulse jet

- Manómetro diferencial de presión

- Tambores recolección de polvo

- Ductos para conectar al gabinete

- Decantador intermedio permite mantener alta aspiración en cabina evitando que granalla buena sea retirada del equipo

- Kit silenciador para reducción de ruidos

- Plataforma mantenimiento

Componentes Eléctricos

- Panel de comando de fuerza y operación del equipo

- Amperímetros para control de funcionamiento de turbinas

- PLC para control automático de proceso.

- Fabricados conforme norma IEC, Nema, UL de acuerdo a necesidad

- Set sensores de movimiento componentes

- Aire acondicionado

- Arrancadores suaves

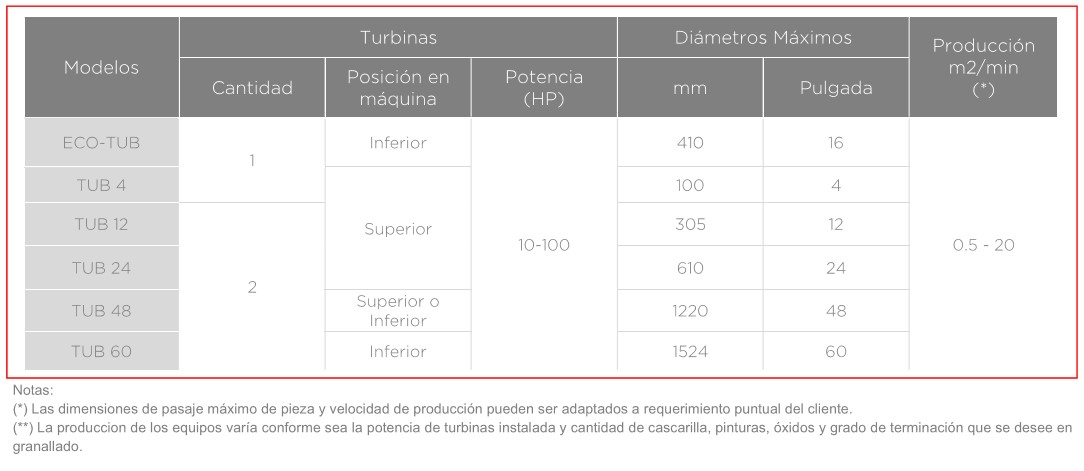

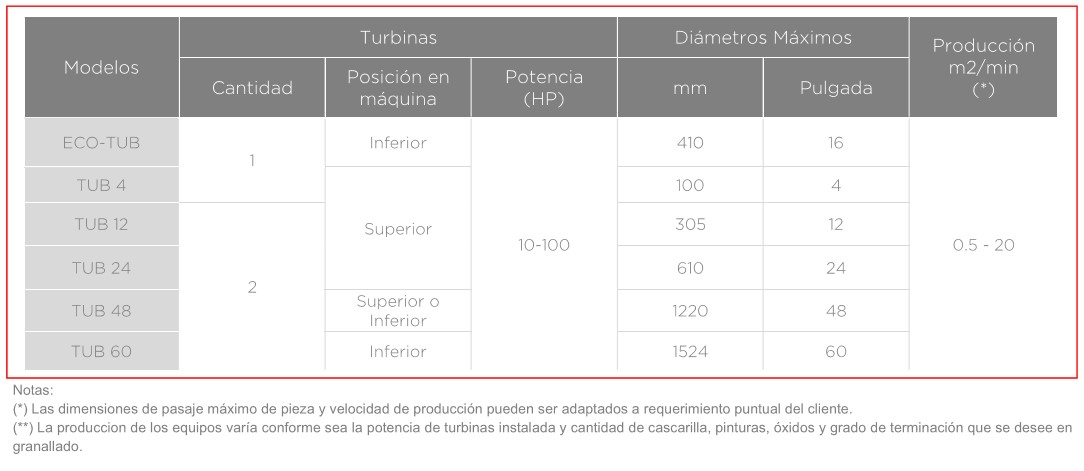

Detalle Técnico – Granalladora de Tubos - TUB

Notas:

(*) Las dimensiones de pasaje máximo de pieza y velocidad de producción pueden ser adaptados a requerimiento puntual del cliente.

(**) La produccion de los equipos varía conforme sea la potencia de turbinas instalada y cantidad de cascarilla, pinturas, óxidos y grado de terminación que se desee en granallado.

(***) Si los equipos que están necesitando no los encuentra en este catálogo, por favor póngase en contacto con nuestro departamentos de ventas o Ingeniería, que podrán ayudarlos a desarrollar el mejor equipo que se adapte a sus necesidades, buscando reducir sus costos de operación y el aumento de rentabilidad en sus sistemas de producción.

Ventajas en la Utilización de 2 equipos Automáticos en línea para procesos de Granallado de Tubos.

- Trabajando con 2 equipos de granallado en línea, además de mejorar la calidad de granallado, se puede duplicar la producción con similar costo por metro cuadrado procesado.

- Se optimiza el uso de la granalla aprovechando un porcentaje que es descartado de la 1er maquina.

- Se logra el perfil necesario, y se disminuye el riesgo de falla de revestimiento por contaminación superficial.

- Alto volumen de producción con mínimo costo operativo.

- Mayor homogeneidad de terminación en las piezas procesadas.

- Proceso automático de granallado, no requiere mano de obra especializada.

- Con un correcto funcionamiento del equipo, no existen problemas de salud en personal o daños en las instalaciones no contaminando el medio ambiente

Ampliar información...

Equipos alternativos y complementarios

Línea de Granallado Granallado Interno de tubos TUB-I

- Dos opciones de proyección de abrasivo

- Línea de granallado interno TUB-I-AC impulsando el abrasivo por aire comprimido para procesar tubos en un rango desde Ø3/4” en adelante utilizando una o múltiples lanzas de granallado

- Línea de granallado interno TUB-I-TR para procesar tubos desde Ø20” en adelante, impulsando el abrasivo con turbinas centrifugas en producciones que varía entre 2 a 7 m2/minuto de granallado por cabezal

Ampliar Información...

Línea de Granallado PER y EST

- Equipadas con cuatro o más turbinas de granallado procesan todo tipo de materia prima incluyendo tubos, spools, tubos curvados, placas, perfiles ángulo, I, H, estructuras soldadas y accesorios.

- Recomendados para procesos que requieran flexibilidad de trabajo los equipos PER permiten un rápido set-up para procesar diferentes diámetros o piezas con forma (spool o estructuras)

Ampliar información...

Línea de Granallado y Pintado 3D para todo tipo de Estructuras Soldadas

- Instalaciones de granallado, pintura y secado de flujo continuo 3D desarrolladas para procesar todo tipo d

e estructura soldada, perfiles, planchas, satisfaciendo las demandas de todo tipo de industria metalmecánica

e estructura soldada, perfiles, planchas, satisfaciendo las demandas de todo tipo de industria metalmecánica

- Utilizada en lineas de procesos que requieran alta producción, flexibilidad de proceso y gran variedad de piezas, permiten aplicar revestimientos en elementos de diferente formas, pesos y tamaños

Ampliar información...

Cuartos de granallado manual

- Proceso de granallado flexible permite granallar todo tipo de piezas que, debido a su tamaño o complejidad, no pueden procesarse en máquinas granalladoras automáticas

- Uno o más operadores trabajan dentro del cuarto de granallado utilizando equipos de protección personal

- Sistema de presión con control a distancia hombre muerto (dead man) para proyección del abrasivo

Ampliar información...

Equipos Especiales

- Granallado interno y externo de cuplas para la industria del petróleo en proceso manual o automático

- Equipos de shot peening para el procesamiento interno y externo de roscas de tubos

- Línea completa de granallado y pintado en polvo de tubos y barras de 1/2 a 4

- Granalladoras portátiles por circuito cerrado por aire comprimido CYVAC para hacer procesos localizados de granallado

- Granalladoras portátiles por circuito cerrado por turbinas GPV para el granallado externo de tubos

Ver videos relacionados

Proyectos Especiales: En caso de que el equipo que necesita no se encuentra en estas páginas, por favor, póngase en contacto con nuestro departamento de Ingeniería y Ventas, para que puedan ayudarlos a desarrollar el mejor equipo que satisfaga sus necesidades, buscando reducir sus costos de operación y aumentar la rentabilidad sus sistemas de producción

Descargar el catálogo (PDF)

Cym Materiales SA presenta TUB: su línea completa de máquinas para el granallado externo de tubos utilizados en la fabricación de gasoductos, oleoductos, acueductos y otras industrias.

Cym Materiales SA presenta TUB: su línea completa de máquinas para el granallado externo de tubos utilizados en la fabricación de gasoductos, oleoductos, acueductos y otras industrias.

e estructura soldada, perfiles, planchas, satisfaciendo las demandas de todo tipo de industria metalmecánica

e estructura soldada, perfiles, planchas, satisfaciendo las demandas de todo tipo de industria metalmecánica