Cym Materiales Argentina y Metalcym Brasil fabrican equipos de granallado automático para estructuras soldadas, placas, perfiles, barras, flejes, pletinas, chapas, tubos spools y andamios tubulares de pasaje continuo adaptándose a la necesidad de cada cliente.

Cym Materiales Argentina y Metalcym Brasil fabrican equipos de granallado automático para estructuras soldadas, placas, perfiles, barras, flejes, pletinas, chapas, tubos spools y andamios tubulares de pasaje continuo adaptándose a la necesidad de cada cliente.

Tres modelos de granalladoras permiten seleccionar el equipo correcto para cada aplicación.

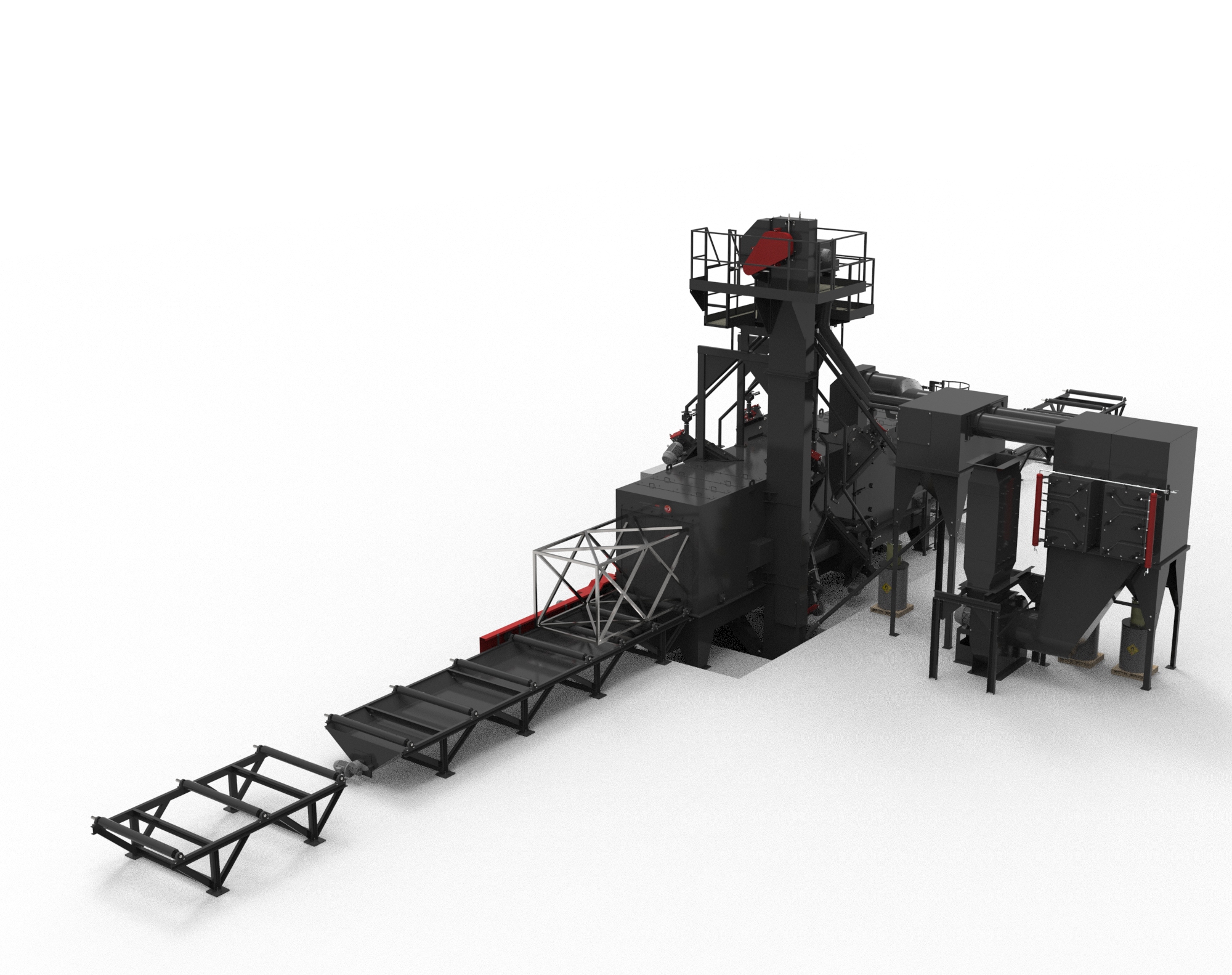

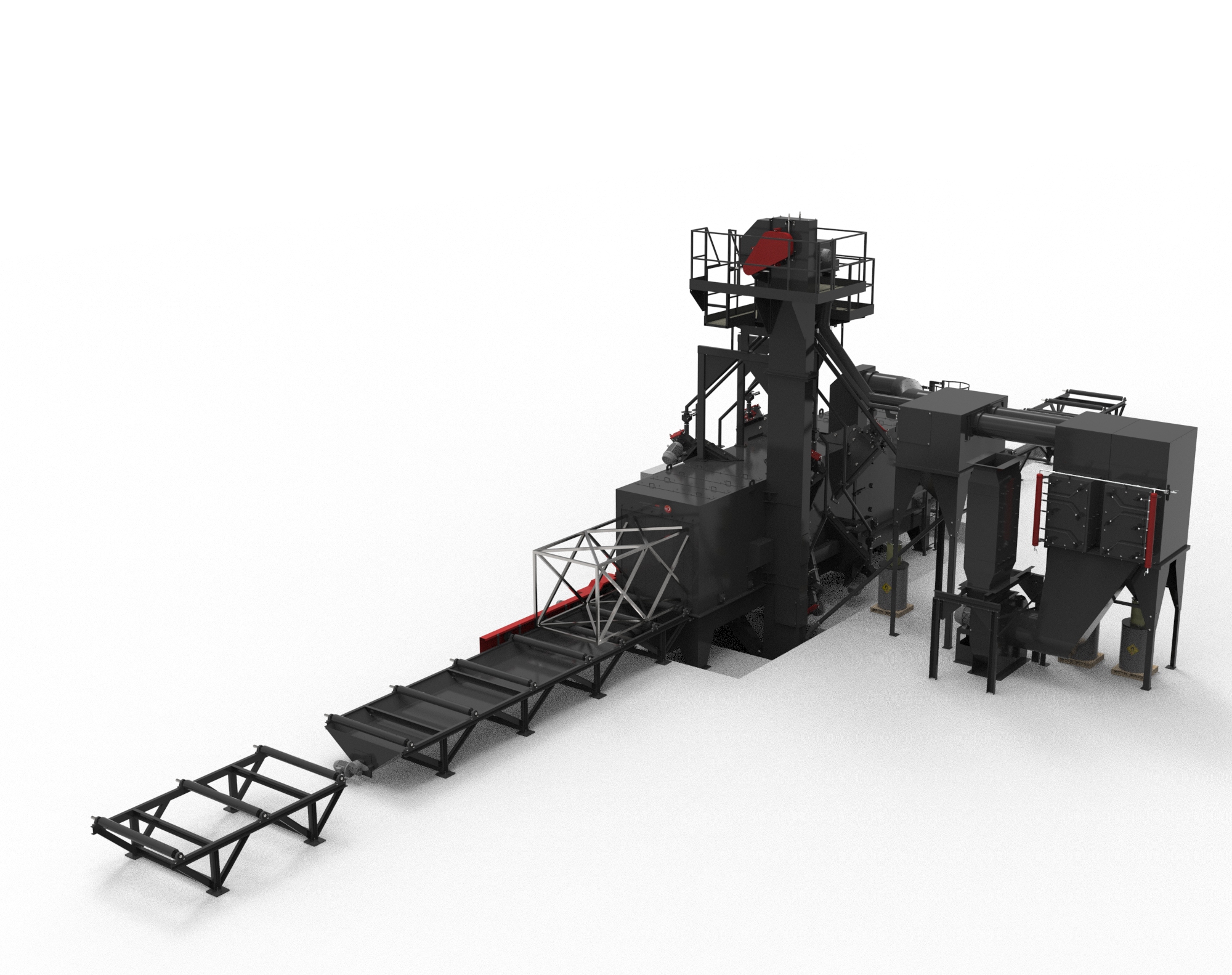

- Línea de máquinas granalladoras PER-R las turbinas están ubicadas a 90° respecto del pasaje de piezas y son ideales para granallar materia prima sin procesar como perfiles H, I, L, tubos, etc

- Línea de granalladoras PER-I además de granallar materia prima permite procesar estructuras soldadas simples ya que en este caso a diferencia de la línea R tiene las turbinas inclinadas respecto del pasaje de piezas. En estos equipos se pueden procesar estructuras complejas pero conforme sea la complejidad de la misma es posible que tengan que procesarlas dos veces para que queden correctamente granalladas

- Por último la línea de granalladoras EST permiten procesar todo tipo de estructuras soldadas. Los equipos poseen 8, 12 o 16 turbinas inclinadas conforme sea la sección de piezas a granallar.

Según sean las características del proceso y los requerimientos de cada cliente, las piezas pueden trasladarse con cama de rodillos paralelos para pasajes horizontales o transportadores aéreos, permitiendo estos últimos procesar piezas en carga suspendida trabajando en línea con procesos de pintura.

Los principales usos y aplicaciones de los equipos de granallado en la industria de fabricación de acero son los siguientes

- Pre-granallado de materia prima

- Proceso previo a la fabricación de estructuras soldadas

- Eliminación de laminilla y oxido mejorando los procesos de corte, perforado, soldado, etc

- Disminuye el nivel de polvo en las instalaciones

- Granallado de estructuras soldadas

- Proceso previo a la aplicación de un recubrimiento (pintura)

- Deja la superficie limpia, libre de oxidos y laminilla

- Aumento de la rugosidad superficial mejorando el anclaje del recubrimiento a aplicar

Detalle Técnico - Granalladoras de Estructuras Soldadas - EST

Ventajas en la utilización de granalladoras automáticas

- Alto volumen de producción con mínimo costo operativo.

- Mayor homogeneidad de terminación en las piezas procesadas.

- Proceso automático de granallado, no requiere mano de obra especializada.

- Utilizando transportador aéreo para procesar piezas en carga suspendida permiten trabajar en línea con procesos de pintura.

- Con un correcto funcionamiento del equipo, no existen problemas de salud en personal o daños en las instalaciones no contaminando el medio ambiente.

Equipos alternativos y complementarios

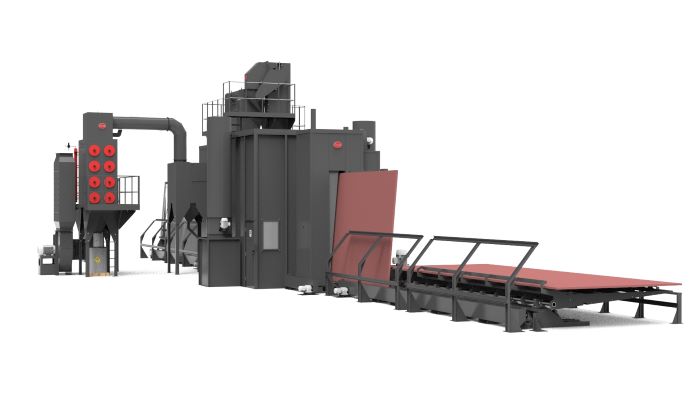

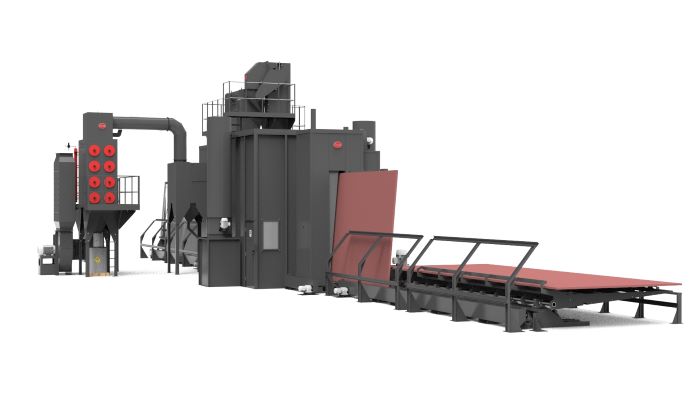

Línea de Granallado y Pintado CH-V

- Especialmente diseñados para procesar planchas en posición vertical

- Permiten trabajar con granalla angular generando altas rugosidades con excelente perfil de anclaje

- Los equipos de granallado se complementan con cabinas de pintado automático y hornos de secado para aplicaciones de shop-primer

- Menor costo de inversión y costo operativo que los equipos CH-H de pasaje horizontal

- Sin posibilidad de acumulación de abrasivo en las chapas, no requiere el uso de cepillos giratorios y sopladores de abrasivo

Ampliar información...

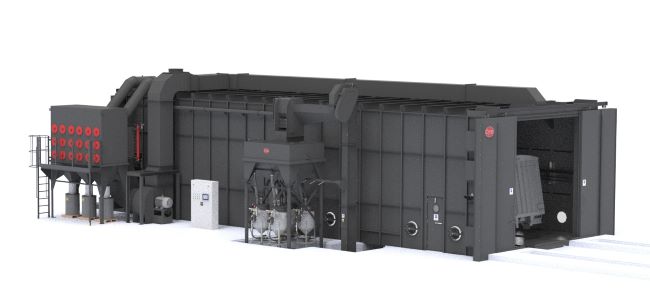

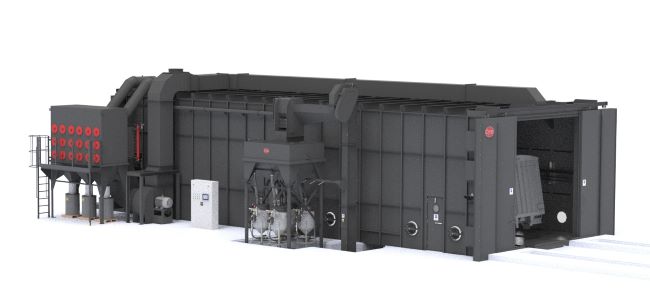

Líneas de Granallado y Pintado de Planchas y Perfiles - Línea CH

- Líneas automáticas para el granallado y pintado de planchas, perfiles y tubos

- Recomendadas cuando los tiempos de fabricación o almacenamiento de materia prima sean largos.

- Dos formas de procesar la materia prima

- En pasaje horizontal (CH-H) para materias primas, placas, perfiles y tubos

- En pasaje vertical (CH-V) para placas

- Velocidades de producción de 1 a 8 m/minuto

- Las máquinas de granallado se complementan con cabinas de pintura y hornos de secado en línea para aplicaciones de imprimación en taller, evitando así la manipulación innecesaria de piezas con alta productividad y bajo costo operativo.

Ampliar información...

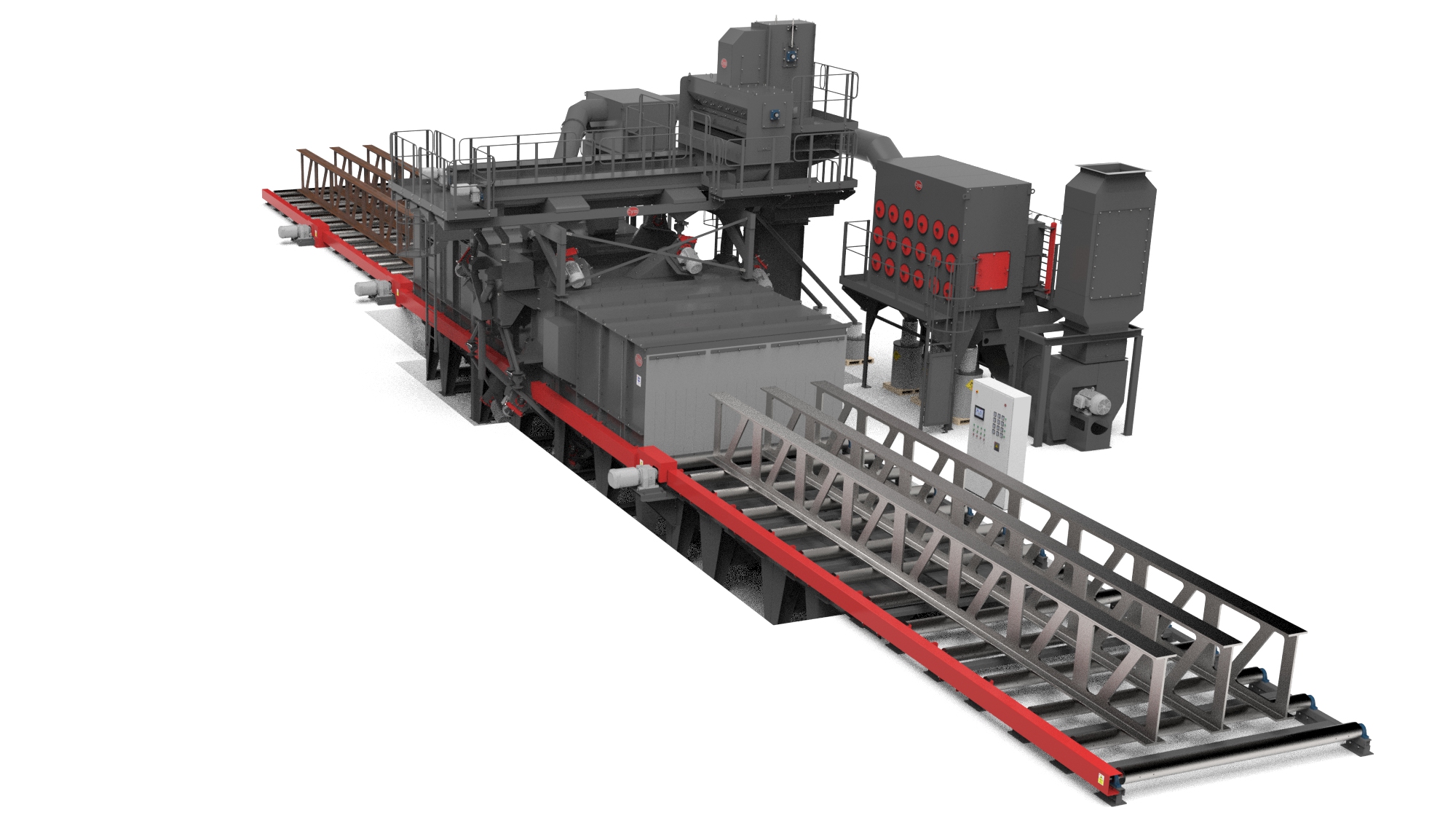

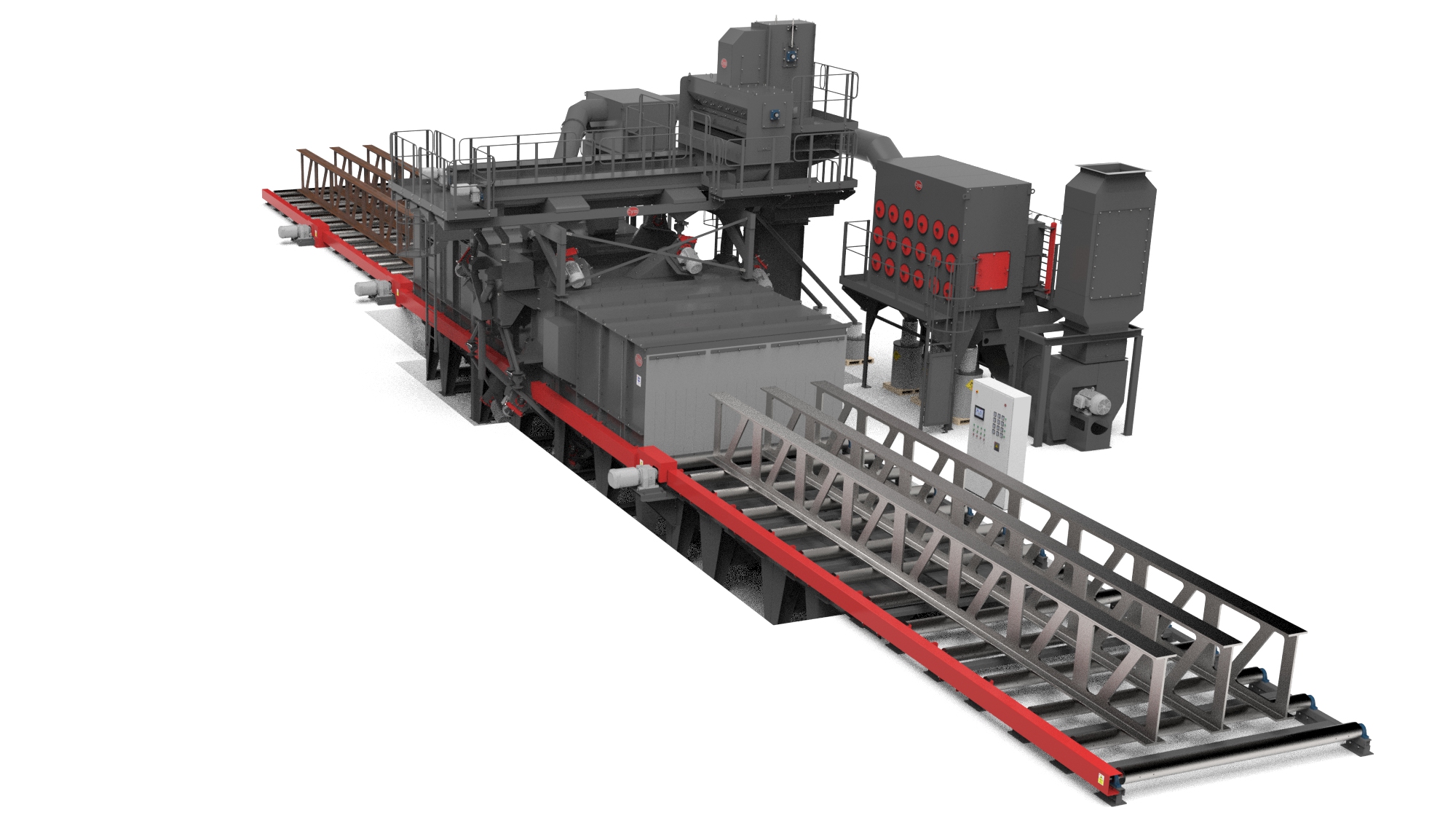

Línea de Granallado y Pintado 3D para todo tipo de Estructuras Soldadas

- Instalaciones de granallado, pintura y secado de flujo continuo 3D desarrolladas para procesar todo tipo de estructura soldada, perfiles, planchas, satisfaciendo las demandas de todo tipo de industria metalmecánica

- Utilizada en lineas de procesos que requieran alta producción, flexibilidad de proceso y gran variedad de piezas, permiten aplicar revestimientos en elementos de diferente formas, pesos y tamaños

- Su concepto 3D reduce el área ocupada en planta promediando un espacio de 15m x 30m para una instalación tipo de dos cabinas de pintura con sus respectivos hornos de curado, procesando en esta unas 45 ton. de acero por turno de trabajo, minimizando tiempos muertos y daños en las piezas por manipulación con un mínimo costo operativo.

Ampliar información...

Cuartos de granallado manual

- Proceso de granallado flexible permite granallar todo tipo de piezas que, debido a su tamaño o complejidad, no pueden procesarse en máquinas granalladoras automáticas

- Uno o más operadores trabajan dentro del cuarto de granallado utilizando equipos de protección personal

- Sistema de presión con control a distancia hombre muerto (dead man) para proyección del abrasivo

- Los cuartos pueden automatizarse agregando robots o manipuladores de boquillas, eliminando el trabajo manual

Ampliar información...

Proyectos Especiales: En caso de que el equipo que necesita no se encuentra en estas páginas, por favor, póngase en contacto con nuestro departamento de Ingeniería y Ventas, para que puedan ayudarlos a desarrollar el mejor equipo que satisfaga sus necesidades, buscando reducir sus costos de operación y aumentar la rentabilidad sus sistemas de producción.

Ver videos relacionados

Descargar Catálogo

Cym Materiales Argentina y Metalcym Brasil fabrican equipos de granallado automático para estructuras soldadas, placas, perfiles, barras, flejes, pletinas, chapas, tubos spools y andamios tubulares de pasaje continuo adaptándose a la necesidad de cada cliente.

Cym Materiales Argentina y Metalcym Brasil fabrican equipos de granallado automático para estructuras soldadas, placas, perfiles, barras, flejes, pletinas, chapas, tubos spools y andamios tubulares de pasaje continuo adaptándose a la necesidad de cada cliente.